When the State of Kentucky is mentioned, one of the first things to come to mind is horses. There is one horse for every twelve people within its’ borders. But not to be overlooked is Kentucky’s chief export, bourbon. There are 1 million more barrels of this uniquely American whiskey than there are residents living in the Bluegrass State. In fact, they even outnumber the humans and horses combined! Even if you never take a sip of this sweet whiskey, the story behind it is fascinating.

The immediate question that comes to mind is: Why is there so much bourbon and whiskey being produced in Kentucky and Tennesee? Well, the answer to that is the water quality. Both states have a layer of limestone that filters the ground water, and there is virtually no iron in it. Iron content is highly detrimental to producing whiskey.

So what is it that makes bourbon bourbon, and not just whiskey? Well, a number of legal requirements must be met. It must be 51% corn based, made and aged for a minimum of two years in new, charred oak barrels and be made in the United States. Also, the distilling process must not allow the product to exceed 160 proof when leaving the still, not enter the barrel more than 125 proof, and be at least 80 proof at bottling. No additional flavoring may be added, and only water can be used to lower the proof. With these stringent standards, a distiller must become creative to make their product stand out from the others. One of the best at marketing and producing a unique product is the Samuels family, crafters of the brand Maker’s Mark.

To understand the history of this brand, you have to go back a long way. Founder Bill Samuels, Sr. was the 4th generation to distill bourbon in the family. He actually was the 6th, but the first two didn’t pay taxes, so his wife Margie said they didn’t count. In 1953 he purchased the run down Burks Distillery, just northeast of Loretto, Kentucky, for $35,000. That operation had the distinct honor of being the oldest producer of bourbon in the world, beginning back in 1805. While it isn’t clear if any of the buildings from that original operation still exist, some of them are definitely old. The roads to get to the property were (and still are) narrow and winding.

Setting the stage for Maker’s Mark, a number of events took place. When the bourbon industry resumed operations after Prohibition, their offerings were anything but smooth…as the product was rushed to the thirsty consumers. In fact, Margie was reported to have said “That s*** will blow your ears off!” When the U.S. entered World War II, President Roosevelt shut the bourbon industry down to preserve grain for the war effort. Bill Samuels, Sr. had been pressuring his father for some time to consider changing the family recipe, but was met with the reply “They’ll drink what we give them.” The T.W. Samuels Distillery in Deatsville, Kentucky was sold out of the family in 1943, and Bill Samuels, Sr. was out of a job. When the distillery resumed production under a different name after the war, the whiskey had acquired a burned smell and taste. Even though Bill was no longer with the company, he wanted to distance himself from them…and that was the impetus for purchasing the Burks Distillery. He ceremoniously burned the family recipe, and as the story goes, set the curtains in the living room on fire in the process. 🙂

So with bourbon requiring a minimum of two years of aging, the question of how to come up with a new recipe was raised. Samuels developed seven different concoctions using variations of wheat instead of rye, as the latter tends to impart a spicy note into the product. Margie proceeded to bake loaves of bread from each one. The loaf that tasted the best to them was the one that used red winter wheat.

With the recipe in hand, they had to come up with a name for their bourbon. This is where Margie stepped in and set them on the path to success. She was a collector of English pewter, and she knew each pewter maker had their own distinctive mark on the bottom of each piece. She developed the round maker’s mark with a star to signify the Star Hill family farm and distillery, and the ‘S IV’ to commentate that her husband was a fourth generation of Samuels to be a distiller. She designed the label and lettering to look hand crafted, lending authenticity to this new brand.

Spelling whiskey without an “e”, is a tip of the hat to the Samuels’ Scottish heritage. From there, she designed a unique bottle to the bourbon industry, combining both square and round elements, similar to a cognac bottle.

To top it off, she insisted on hand dipping the neck of the bottle in red wax to add a distinctive look. At first, Bill didn’t like it, as he felt it made it too difficult for his customers to open the bottle. When Margie insisted they use it, he had a pull tab made that would withstand the 350 degree wax that allowed its easy removal. The dripping wax now carries a U.S. patent.

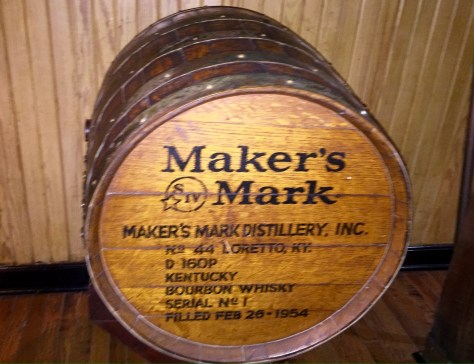

With all the pieces in place, production commenced. The first barrel, proudly displayed in the distillery, was filled on February 26, 1954. The first bottle was filled on May 8, 1958. Since then, the aging process has been extended to between 5-3/4 and 7 years, depending on when the tasters determine the barrel is ready.

On Friday, October 21, Diana and I drove up to Loretto for a tour of the distillery. We really didn’t know what to expect, as we had never been to one. What we found was a setting very similar to the wineries of northern Michigan, only with a quaint, historic twist.

Nestled into the hills of Happy Hollow, the Samuels’ Star Hill Distillery is downright charming.

This is the same building shown in the sepia-tone photo at the beginning of the post. It’s the actual distillery that Bill Samuels, Sr. purchased back in 1953 and is a National Historic Landmark.

All of the buildings on the property are painted chocolate brown, and the windows are outlined with red shutters….the same color as the sealing wax…with cutouts of the Maker’s Mark bottles in them.

Stepping inside the distillery building, one of the first things you see is the roller mill ….

…that reduces the grain from what is seen on the left to the smaller jars on the right.

From there, it is mixed with spring water and put into large, century old cypress vats. Yeast is added to the mash, which generates carbon dioxide and heat, and the mash is allowed to ferment for three days. Maker’s Mark has its own strain of yeast that is 150 years old, and is a closely guarded secret. We were invited to dip our fingers in and taste the mash, which our tour guide said tasted like warm beer. I stopped just short of my mouth and asked him “is it gluten-free at this point?” He replied “No, it’s not.” I had to take his word on the beer comparison…but boy did that room smell good! The higher alcohol content further down the line would take care of the gluten…and any impurities from my tour-mate’s fingers. 😀

The mash is then introduced into the still, which seperates the alcohol from the mash through heat. It is then distilled a second time in a still referred to as a doubler.

From the doubler, the alcohol runs into these spirit safes, which are large copper receivers. There is a hydrometer in the glass portion of each safe that measures the alcohol content of the spirits entering the receiver. The stillman’s job is to know when to seperate the undesirable heads and tails (the first and last portions of the run) from the pure spirits in between. He or she uses only the hydrometer and a thermometer to do so. The name spirit safe comes from Scotland, where the tax man held the only key to the padlock at the top…thus keeping the distillery workers from siphoning off pure spirits before the government had a chance to tax them.

At this point, the product is referred to as white dog….or what most of us would have called ‘white lightning’. Samples are diluted for the tasting panel and, if the batch passes muster, it is put into the barrels for aging. Remember from earlier in the post, these are new American oak barrels, and they are charred or toasted to a selected degree to allow the spirits to blend with the flavors of the wood. That is required by law.

The barrels are stored in huge warehouses, called rackhouses. At Maker’s Mark, they rotate the barrels from to top to the bottom of the warehouse throughout the aging process, so the differations in temperature can be evened out. Some of the bourbon evaporates through the pores of the barrel staves, which is referred to as the angel’s share. Judging by the sweet aroma of the rackhouse, there are some very happy angels in Kentucky!

In specialty products, such as the higher end Maker’s 46, fully aged bourbon is poured into previously used Maker’s Mark barrels that have different seared French oak staves in them. The bourbon is then aged an additional nine weeks to bring out a different flavor. It’s even possible to order a special batch for yourself under their Private Select program, which uses a combination of 5 different types of staves they have available. Oh, my… 😀

Once the aging process is complete…again, determined by a panel of tasters… it’s off to the bottling line!

First step is to unload the bottles and put the boxes on a conveyer for use at the other end of the line.

The machine then flips the bottle over and rinses the bottle out with none other that Maker’s Mark.

The bottle is then filled…

…then capped…

…and labeled. It is here that I should mention that the Margie Samuels-designed labels are printed and cut out on the property, using an archaic Chandler & Price printing press and a hand operated die cutter.

Now, the magic happens:

Four women, standing at four seperate stations, hand dip each bottle with the distinctive wax. If the wax drips onto the label, it is rejected. I had visions of Lucille Ball and her friend Ethel and their famous bit wrapping chocolates in a candy factory. 😃

The bottles are then run through a chiller to set the wax.

From there, they are returned to their boxes and sent on ther way!

Our next stop was the tasting room. We were given 4 samples: Maker’s White (which is basically White Dog, diluted to lower the alcohol content), Maker’s Mark, Maker’s 46 and a version of Maker’s Private Select that was made for Keeneland Horse Track in Lexington. Maker’s White isn’t really a bourbon…as it hadn’t been aged…but it was pretty smooth. Maker’s Mark is sweet, smelling a bit like caramel and vanilla. It is smooth as it hits your palate, and it is warm on the back of your tongue. The other two were very good, albeit a touch heavier. We can see why Maker’s Mark has such a loyal following.

After a quick trip to the gift shop…. where anything Maker’s Mark was available, including being able to dip your own bottles in wax….we were on our way. After we left the distillery, we made our way into the town of Loretto, to see what was there. There wasn’t much to see, until we drove to the other side of town and our jaws dropped.

There was a campus of at least 20 giant, chocolate brown rackhouses in front of us, with more under construction! I guess if a company ages their product for an average of 6 years, they have to store a lot of barrels! Very impressive.

So cheers to a really fun day at Maker’s Mark! We didn’t know what to expect, and we thoroughly enjoyed our tour.

—————————————

Search and shop exploRVistas Amazon link *here*

—————————————

explorRVistas is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon .com. Shopping through our link does not add anything to your cost, but it does help support this blog. Thank you for shopping through exploRVistas!

I knew you’d find interesting places to visit during your stay!

I’d say have one for me, but seeing as you’re already gone that wouldn’t be possible. So, have a good memory for me!

I love those copper kettles — two of them looked like stackable laundry equipment — that would look really classy in an RV, eh? 🙂

I can remember taking all manner of tours over the years and it seems that with food safety rules and industrial safety regulations so many tours don’t take you to SEE much of anything and so many of them sit you in a room and show you a movie after which you take a hike to see interesting buildings but no <>. Funny how the world changes around us. I think the last distillery I toured was Hiram-Walker and that was a ‘few’ years ago.

Glad you’re having fun. You need a break from the hard work.

LikeLiked by 1 person

Thanks, Peter! I knew it was going to be a great tour when the guide said “take all the pictures you want!” How cool is that?

At this point at Amazon, we are working four 10 hour days and have three off, so we are managing to get some touring in. A little tough finding time to write about it, but trust me when I say we are enjoying our time here to its fullest. 😀

LikeLiked by 1 person

Real kewl!

That’s the only way — enjoy each moment.

Late dinner with family last night: I can’t imagine living with three kids between 7 and 13…. My hat is off to modern day parents with kids into fencing, and robots and video games…. yikes!

LikeLiked by 1 person

I am going to be the “smartest” person in the group when we take our tour of the distillery next month! Since horses and bourbon and friends are all high on my list of favorite things……I’m really looking forward to our time there. Great post on this interesting process – I could almost smell the room 🙂

LikeLiked by 1 person

You will LOVE Kentucky, Jodee! I’ll write more about the horses as we go along, as they are absolutely beautiful!

LikeLike

As usual, Jim, your article was very interesting and informative. Of course, now I want to go get some Maker’s Mark.

LikeLiked by 1 person

Thank you, David! I’m thinking Nancy and you can incorporate a tour into your next trip to Michigan. We didn’t get a bottle that day, but after the extra research we did on this post, there is one in our future!

LikeLike

We are not real fans of bourbon or whiskey but the process looks very interesting. I am sure when we are in that area we will do a couple tours.

LikeLiked by 1 person

I had a run in with Jim Beam at my bachelor party in 1982 that steered me to beer, Jim. My gluten allergy led me to wine and cider, so I’ve never really been one to retry bourbon. I think I could definitely enjoy a shot of Maker’s on the rocks every now and then. I still really prefer a glass of dry white wine the best. Leelanau spoiled me. 🙂

LikeLike

Glad you are enjoying KY to its fullest! My fav Bourbon, of all the tours we did, was Makers Mark 46. Just like to sip on it a bit every once in a while. Just wish it was so much $$$!

LikeLiked by 1 person

We are trying to get as much in as we can before the OT hits in a couple of weeks, Kelly! We also have done some other things…just haven’t blogged about them yet. We will have LOTS to talk about with you when we meet up, in regards to packing!

LikeLiked by 1 person

That sounds like so much fun. What an operation. The aging process with wine and liquor is so intriguing. A lot of science involved there.

Bonnie

LikeLiked by 1 person

I highly recommend this tour, Bonnie. Also, the grounds are beautiful. 🙂

LikeLike

While there we did a few of the bourbon trail, but Makers Mark was our favorite. And of course we bought a bottle and I hand dipped it 🙂

LikeLiked by 1 person

That’s so cool, Mona Liza! The place is so interesting, and I loved the setting.

LikeLike

Excellent post, loved the history, and can’t wait to hear more about Amazon. Lee is very interested in packing and inquiring minds want to know 😉

LikeLiked by 1 person

Thanks, Trace! I’ll do a few Amazon posts along with our other stuff. We’ve been trying to take advantage of the great weather, no OT yet, and all the cool stuff to do around here. Loved your beet harvest posts, but still can’t figure out how you found the energy to write! 😅

LikeLike

We have visited a lot of breweries and wineries, but no distilleries yet. We’ll have to put this one on the list. Great post!

LikeLiked by 1 person

Thanks, Bob! There’s an entire bourbon trail down here!

LikeLike